The previous post discussed preparing the edge joint for thin boards.

The second problem involves clamping the joint. Because these are thin boards it is desirable to align the edges as accurately as possible to avoid a significant loss of thickness in the final product. More vexing is the tendency of the joint to explode when clamping pressure is applied. This problem is akin to trying to control the writing tip of an 8 inch long pencil held only by the eraser.

I like #20 biscuits for aligning 3/4″ edge glue ups and #0 biscuits could work for ½” boards, but for the 11/32″ boards shown here I would be concerned about biscuit swelling and show-through. Splines are a hassle which I gave up on long ago. The same goes for those elaborate clamps that use wooden battens to apply pressure on the face of the glue-up while the clamp screws apply pressure to the joint. One option that I have not tried but looks good is the Plano Clamping System.

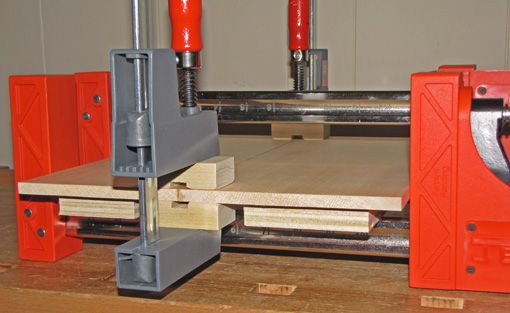

Here is a simple solution that works for me. The boards rest on 3/4″ MDF or plywood platforms. After applying glue and bringing the joint together, I apply just light pressure with the bar clamps. Then I clamp small blocks, with cutouts to vault the glue squeeze-out, across the joint near the ends. I push or tap near the middle of the joint to align it there. Then I apply final pressure with the bar clamps.

There are surely many other methods for edge joining thin stock, notably from instrument makers. I’ve described simple, shop-tested methods that I use. Best wishes for your woodworking.