Moving up the rasp food chain to the hand-cut variety reveals the true capabilities of rasps. These have teeth that are cut (“stitched”) into a polished steel blank by a skilled craftsman using a metal pick and a hammer. The teeth are cut in diagonal rows but the handmade process introduces an important bit of randomness in their placement which creates a tool with control and smoothness in use that is unmatched by machine-made rasps.

It is the feel on the wood and the feedback through the woodworker’s hand which makes these rasps so effective. The teeth cover the surface across the entire width, typically at least 1-1/4″ in a 10″ long model, helping to give a direct sense of where the tool is cutting. Because these tools are used for shaping, their superb sensitivity in the hand is paramount.

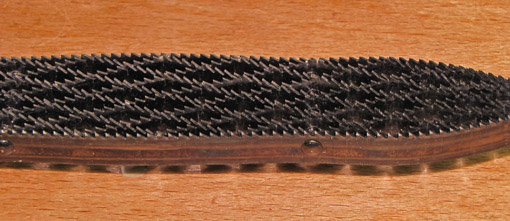

There is an increasing number of hand-cut rasps available but I will comment only the Auriou brand which I have used for several years. I use the 10″ #9 and #13, a combination which has been marvelously effective in shaping legs, one of my favorite things to do in the shop. They’re not cheap but have proven well worth the investment. Here are two sources: Lie-Nielsen and TFWW. Here is a close-up of the #9 and #13 teeth. Click to enlarge.

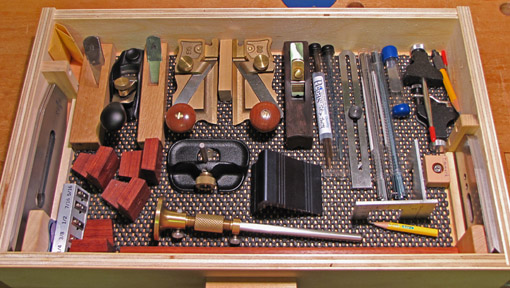

It pays to store rasps so they don’t bang against each other, and keep them clean with the method described here.

Here is a list, not necessarily exhaustive, of other hand cut rasps available. Also, here is a suggestion to Popular Woodworking, Fine Woodworking, and the other woodworking magazines: this would be a good topic review, especially since there is a considerable range of prices. In the meantime, reader comments are welcome.

- Liogier

- Gramercy

- Blu-Dan

- Dragon

- “Hand-cut” from Lee Valley

- “Hand-cut French rasps” from The Best Things (Logier)

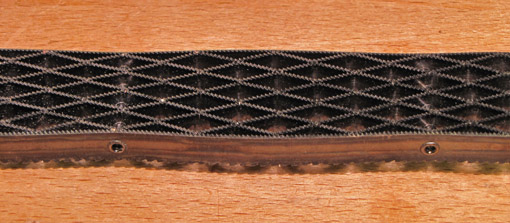

Another tool that is not a conventional rasp but deserves mention in this discussion is the Iwasaki float (“rasp” in at least one catalog) which is effective for shaping. I like my 8″ x 3/4″ “fine” flat Iwasaki. It is essentially a very sharp float with discontinuous arc-shaped teeth, which make the cutting action smoother. When I’ve tried conventional float files on repeated occasions, I found them grabby, though admittedly this was probably due to my inexperience. Nonetheless, the Iwasaki felt good right away.

The Iwasaki is useful in the late stages of shaping to clean up surfaces, and it can even be used to take a bit off tenon cheeks with good control. They are also available in convex profiles. Here is a close up, click to enlarge.

Rasps seem to be looked down upon by some fine woodworkers as less sophisticated than edge tools for shaping. I disagree. I own and use spokeshaves, specialty planes, and gouges. All of these tools have a role in shaping. An excellent quality rasp allows a skilled craftsman to execute just as much control and sensitivity as any of the edge tools. They work!

Next: Disston handles, some technique, and suggested rasp sets to own.