Tip #3: See the line with both eyes if you can.

Most woodworkers feel more comfortable and work more accurately sawing with the line and the saw on a specific side, left or right. For right handers, the most efficient setup has the saw in the right hand and the line to the right side of the midline of the body. Both eyes view the line from the left and see the left edge of the kerf splitting the line and the remaining half-line trailing the kerf. The keeper wood in this case is on the left, the waste on the right. This arrangement is likely to be favored even in the minority of cases in which eye dominance does not match the side of hand dominance.

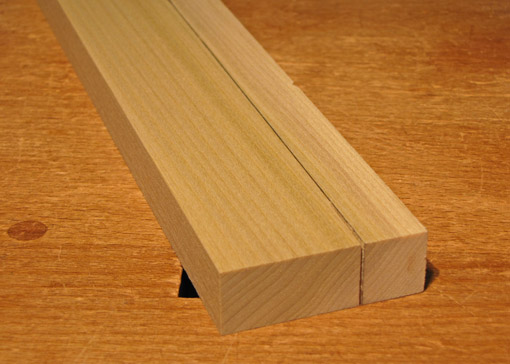

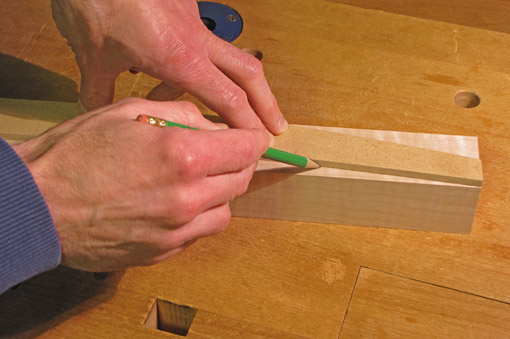

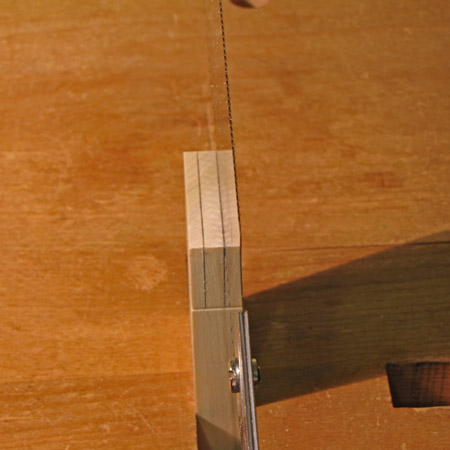

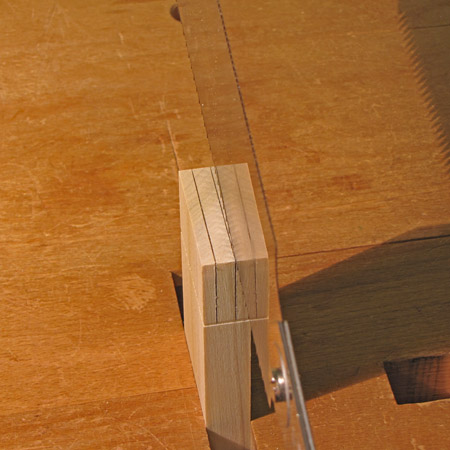

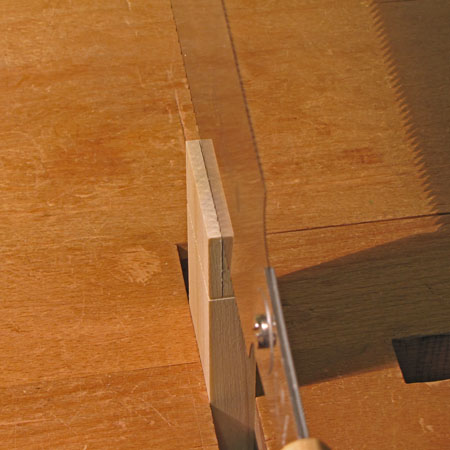

The photo at the top, demonstrating this setup, is the view with the right eye sawing a tenon. Below is the view with the left eye. The small disparity in vantage points permits stereoscopic (high level binocular) vision.

The key element is that both eyes view the line. If you are fortunate to have two good eyes that align properly, your binocular vision is an advantage over seeing the line with just one eye. The eyes also track better working together than alone. Try it.

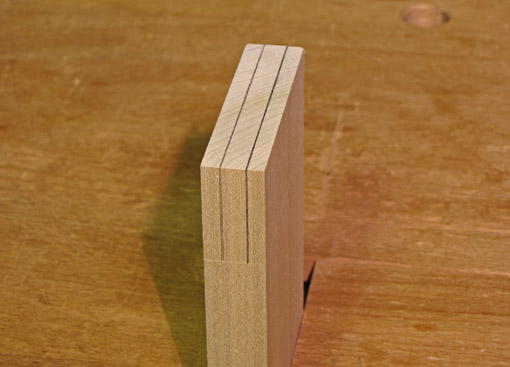

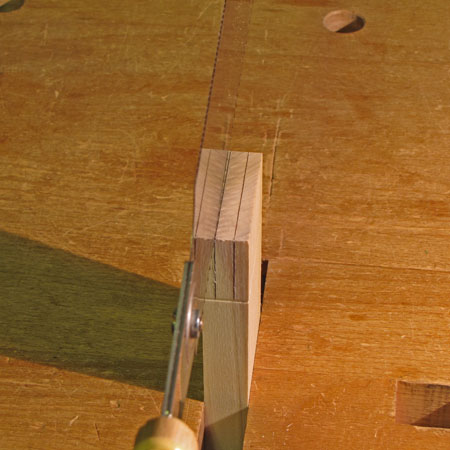

Sometimes this desirable setup cannot be achieved. A right hander finds himself with the right eye viewing the line from the right side of the saw, as in the photo below.

Since it is usually very awkward to shift the head fully to the right of the saw, the left eye views from the left side of the saw, as seen below.

The brain cannot blend these two very different images. One image is functionally “turned off” and you are then effectively working in the less efficient one-eyed mode. Sometimes this cannot practically be avoided.

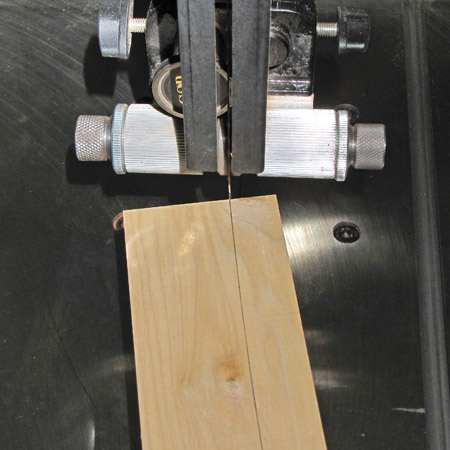

There is another situation to consider. This happens commonly at the bandsaw. One eye, usually the left, gets a good view of the line meeting the teeth, as in the photo below.

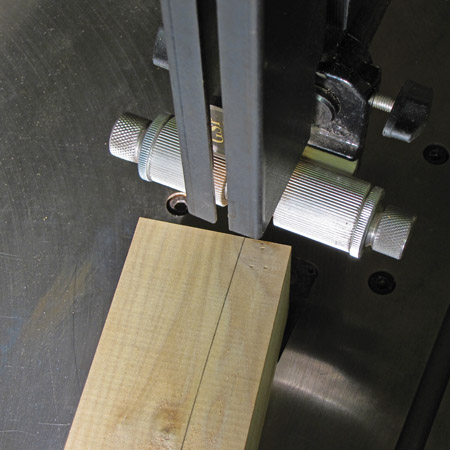

Oops, the other eye’s view is blocked by the blade guide/guard apparatus:

You may sense less visual precision without being immediately aware of the cause. The solution is to arrange your stance so that both eyes have a view of the line where it meets the teeth.

Because of the many sawing situations in the shop, there are exceptions to all of this. The basic principle is nonetheless helpful, and being aware of it can help your sawing.

Good lighting (angle and distance), a good quality line, and proper visual correction for the distance at which you are working, also contribute to seeing the line properly. And, yes, you do have to blow away the saw dust regularly, especially with Japanese pull-stroke saws.

Coming up: Do you need to see all of the lines? Can you? When does seeing them become less important?