These Corradi rasps are the ones I reach for most often. Several years ago, I wrote on choosing and using rasps, highlighting the excellence of hand-cut rasps, specifically the Auriou brand, based on the feel and feedback they provide.

In this regard, for a 10″ cabinet rasp in the finest grain, I still prefer the Auriou #13. However, I’ve come to prefer the Corradi rasps in the coarse and medium ranges. Furthermore, I don’t think there is a big difference between the finest Corradi #10 and its close equivalent, the Auriou #13. Practically, I tend to save the Auriou for the most sensitive work, much like a carefully tuned smoothing plane.

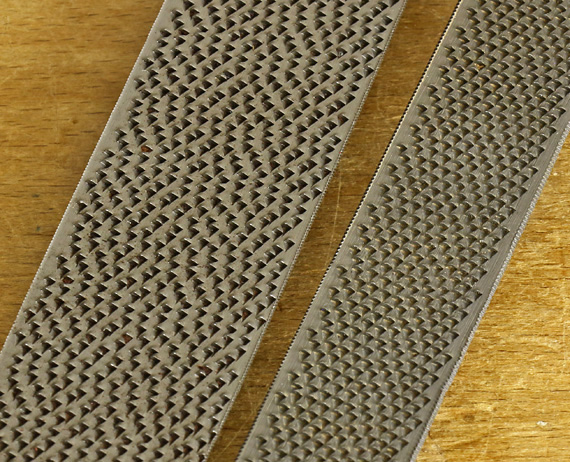

The Corradi rasps have uniform, densely packed, machine-cut teeth with a surface hardness of Rc 65-66, which the manufacturer claims is harder than the best hand-cut rasps at Rc 59-60. In my experience, which is not controlled testing, the Corradi rasps have indeed maintained their sharpness better than the Aurious.

The swirl pattern of the teeth produces a very smooth cutting action, though again, just slightly lacking the superb feedback of the Auriou in the finest grain models. In the medium and coarse grains, I prefer the consistent smoothness of the Corradis. I do, however, wish the Corradi cabinet rasps were shaped to a point like the Aurious.

Heresy, some may say, but I’m only telling you what the wood and my hands have told me. These comments, unsolicited and uncompensated, are only meant to help readers make their own choices.

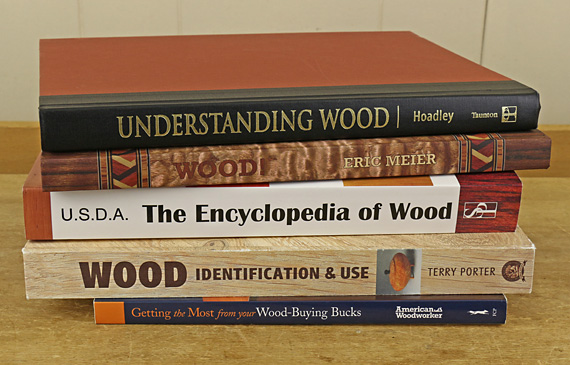

My set of Corradi 10″ half-round cabinet rasps consists of the “Gold” #10 and #8, and the Cabinet #5, from right to left in the photo above. This set is an excellent value at a current total price of $134. By comparison, a single 10″ half-round Auriou #9 costs from $110 – $135, and the finer grains cost still more.

For reference, in 10″ rasps, I estimate the Corradi #10 about the equivalent of the Auriou #13, though the latter is probably a trace finer. Either allows a very easy transition to scraping or sanding.

At the coarse end, the Corradi #5 is about equivalent to an old Nicholson #49 (below, at left and right, respectively), but broader and better. (The Auriou #9 approximates a Nicholson #50.) Looking at the photo above, it seems like a fairly large jump from the Corradi #5 to the #8 but in practice the transition works well.

The three 10″ half-round Corradis – #5, 8, and 10 – plus an inexpensive Shinto double-sided “saw” rasp and a cheap Surform Shaver, with the modification described in an earlier post, form a versatile basic set. I wish Corradi made “ironing” rasps in the form I described in a recent post.

Aside from cabinet rasps, I like the Corradi Gold 6″ #10 flat (“hand”) rasp with one safe edge for smaller scale work such as rounding over tenons. The 4″ Auriou half-round #14 remains the finest rasp in my drawer.

Rasps are often underestimated but high quality versions, skillfully employed, are capable of sensitive, refined work.