We all have squares in the shop. No, no, not nerds, but the 90° measuring tools needed for nearly every project. I will go through what I use in my shop. Not covered here are straightedges. Just squares.

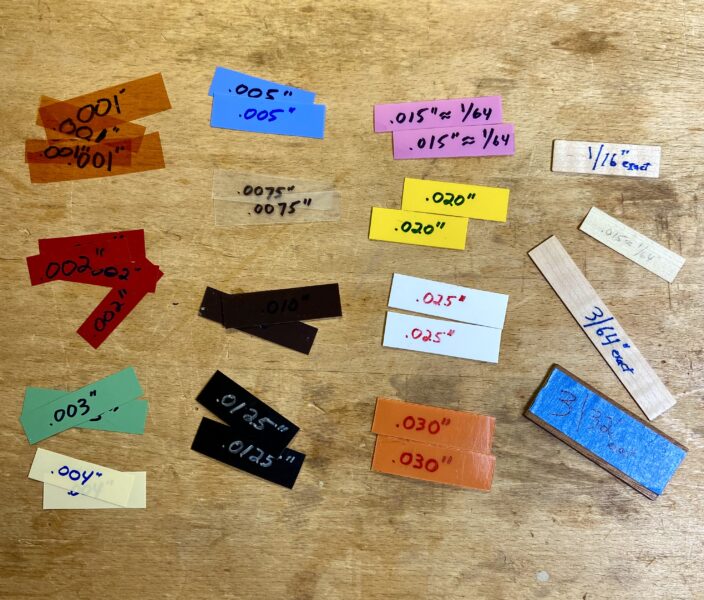

Let’s start with “combination” squares – the blade can be slid along most of its length. I have had Starrett squares for many years. There are other good brands (Woodpeckers has some useful choices) but in this type of tool, Starrett meets, by all I have seen or read, the top standard in documentable square accuracy: .0001” (1/10,000) per 6”. (Woodcraft has, for many years, incorrectly listed +/- .00001”, i.e. 1/100,000”.)

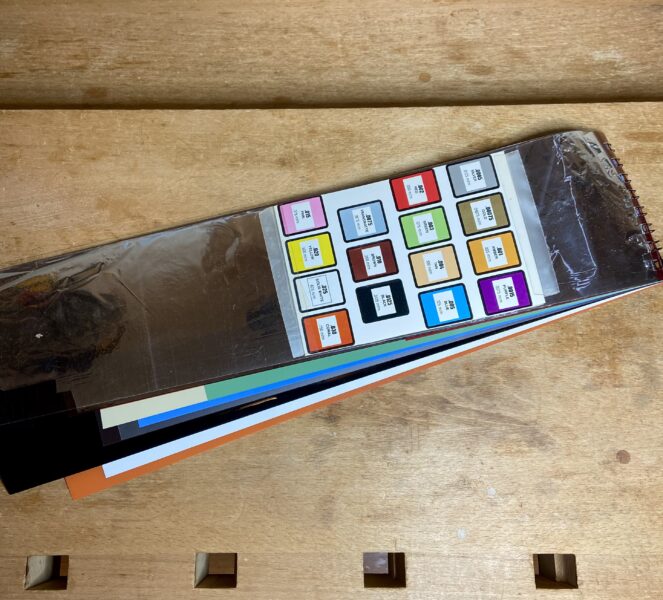

I have Starrett 12”, 6”, 4”, and 2 1/4”. I use them all. (The little one has regular, narrow, and angled blades.) To have only one, I would chose the 12”. The 4” or 6” would be the second choice. The 12” has a 45° angle in the frame, sure to come in handy. The angle slope bubble measure and the pointed scriber get almost no use from me but they do not get in the way. I use other, better tools for that.

Starrett has a huge range of variety including flat or satin-chrome blades, smooth and mildly rough heads, plain straight or straight + angled handle heads, separate 45° head, and variable protractor head, inch and millimeter markings, etc. I suggest to shop around for price and choose what you need. This tool is worth it!

Do we need the 1/10,000 accuracy for everything? Of course not, but it always works in your favor. The best accuracy is valuable for some important things – like tuning machines. The excellent tool can do it all and lasts indefinitely.

The other set of squares that I have are the solid machinist type. The very useful set of three is the 9”, 6”, and 4”. These are more convenient and faster to handle than the combination squares for stock preparation and some joinery. For this type of square, the highly accurate Starrett machinist squares are unnecessarily accurate and expensive.

For the 6” and 9”, I have PEC brand. Their standard is 6/10,000” (about half a thou) for 6”, which well meets the needs. They are well made and reasonably priced. Unlike some less expensive machinist squares, the edges are cut appropriately square-sharp enough without being rounded over.

For the 4” machinist square, I have a Groz. The inexpensive brand meets 28/10,000” for 6” (about 3 thou) which is not good enough. However, I lucked out with this one – it is well under 1 thou based on assessment with a Starrett. It gets lots of convenient use.

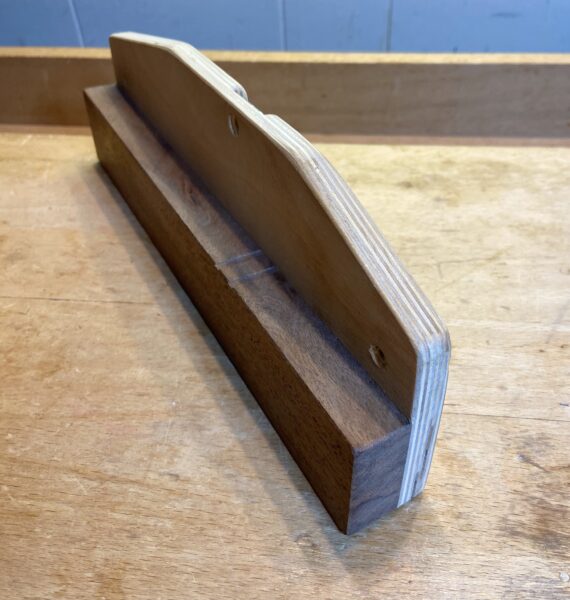

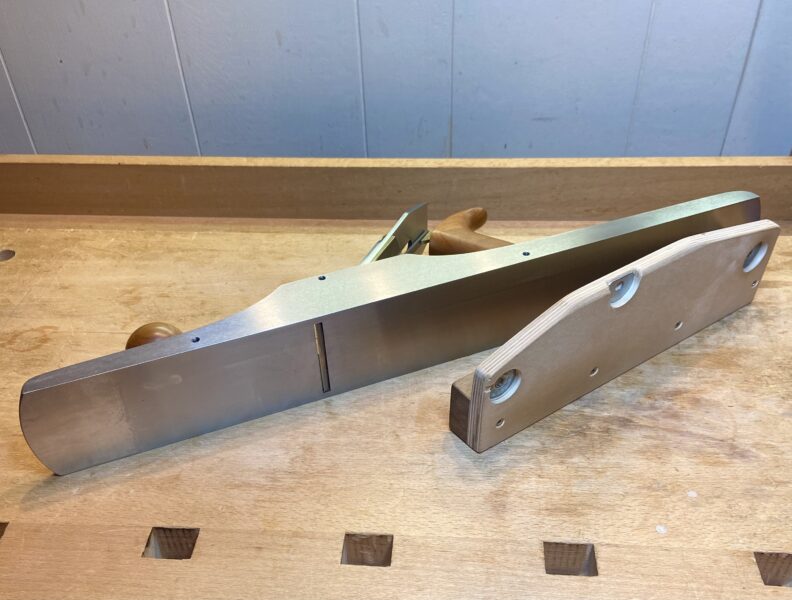

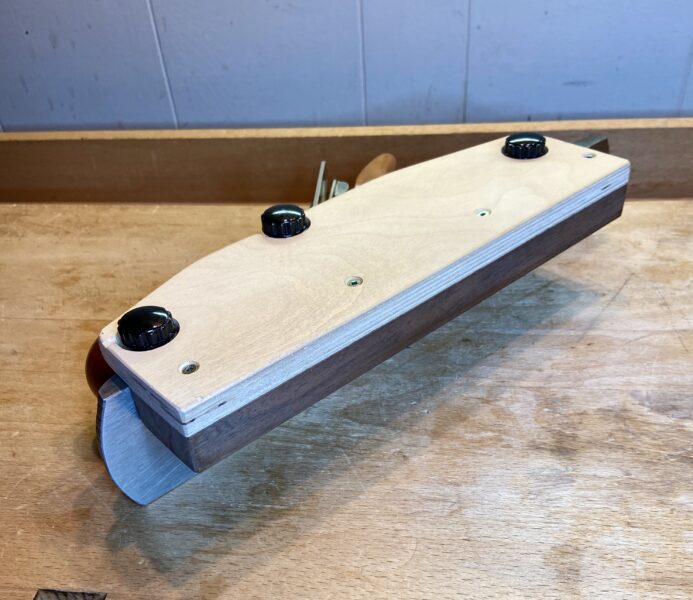

There is one more square in the shop. I made it long ago for checking the square of dovetail parts. The very narrow square blade fits into small areas. I use this one or the little Starrett. Refer to this post:

https://www.rpwoodwork.com/blog/2015/12/31/narrow-square-for-checking-dovetails/

I keep all the squares clean, free of rust, and handled efficiently. Squares really move along the work. Get good ones. I hope this outline helps!