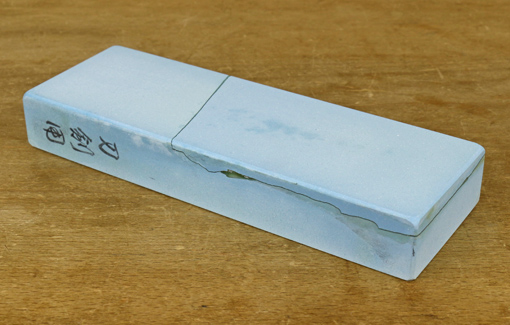

I still think the Naniwa Chosera 10,000 is a great finishing stone for all the reasons discussed in an earlier post but unfortunately it developed a large crack across the lower area after drying from a sharpening session. Fortunately, the loose area cleanly separated with a light tap with a chisel. I epoxied it in place with System Three T-88 and flattened both faces. The top face is uninterrupted and the stone works fine.

So what happened?

Over months of using the stone, I had gravitated to a soaking time of 15 minutes before use, though never longer. Searching the internet produces different recommendations from knowledgeable dealers and users: 15 minutes, at least 10 minutes, 5-10 minutes, no longer than 5 minutes, and some suggest no soaking at all. Everyone agrees that the magnesia binder, which contributes to the excellent feel of these stones in use, will not withstand prolonged soaking. There is also no doubt that the stone should be allowed to air dry slowly and evenly, which I did consistently. There are reports online of hairline cracks and major splits like the one in my stone.

The stone certainly absorbs water and so does not work as nicely in a splash-and-go mode as does a Shapton. As a practical matter, I found that soaking it for, say, 5 minutes is not much better than not soaking at all – it still pretty quickly drinks in the little puddle of water placed on it. This happens a bit slower after a brief presoak but also slows down during the sharpening session even without a presoak.

So, to play it safe and practical, I no longer presoak the stone. I just puddle some water on the surface and work from there, adjusting as necessary. This works out just fine. It’s still a very cool stone to sharpen on and produces excellent results, but I just wanted to give readers a heads up on the potential for cracking and how I chose to deal with it.

By the way, Naniwa now sells the Chosera line as the “Professional Series.”