Here is some help with pencil lines on dark wood. Though knife lines can be modified to produce the advantage of a physical feel for the correct location of a tool such as a chisel, most layout in woodworking is done with pencil lines. Marking out the tails for tails-first dovetailing and curved layout lines for bandsawing are examples.

Graphite pencil lines have a bit of sheen which helps their visibility but I still find them difficult to see, particularly if the line is along the grain on a wood like Claro walnut, which is dark and has color variations. So, motivated particularly by my love of Claro, I have experimented with various white or light-colored pencil and ink lines.

I tried Japanese ink “brushes” and very fine point drafting pens. I do not like marking out in ink because I do make mistakes and have no immediate plans to cease, so no ink for me.

I have scoured art supply stores and experimented over the years with various white pencils, occasionally trying bright yellows and other colors. Most are too soft to retain a sharp point for a practical amount of work.

The best pencil I have found is the Sanford/Prismacolor Verithin White #734. It can be sharpened to a point that is nearly as sharp as a #2/HB graphite pencil. It wears faster than a #2 but the point holds up well enough, especially if used with a light touch. It makes a nicely visible line on walnut. It is not as easily erasable as graphite, but decently enough using a white “plastic” eraser. They cost from 39 cents to a dollar apiece, depending on the quantity and the store.

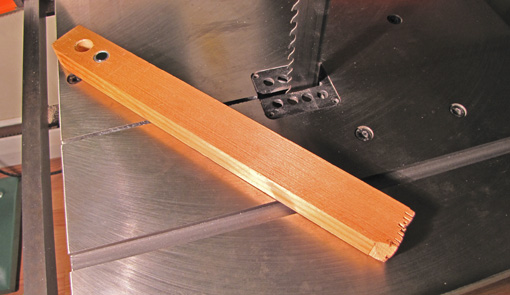

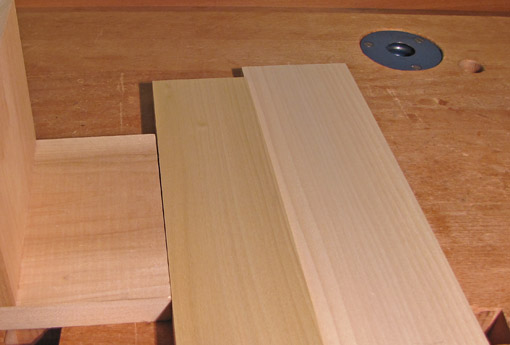

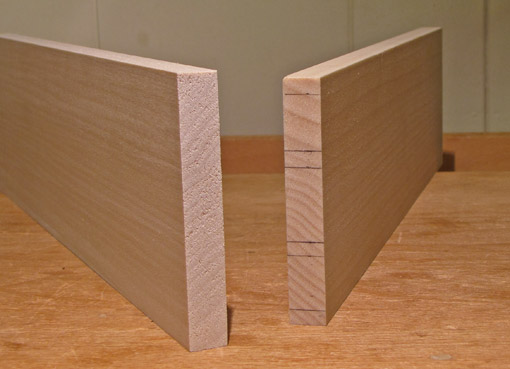

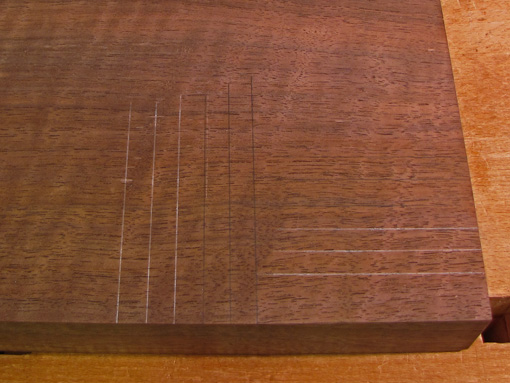

The top photo shows sets of three lines of #2/HB graphite and #734 White going across and along the grain, made from a single sharpening of each pencil. The graphite lines along the grain are barely visible just above the white lines. The photos below show the same lines photographed from different angles.

An alternative is a white 0.5 mm mechanical pencil refill stick made by Pergamano and available from McAllister’s. I have not tried these because they cost $10 for 10 sticks and I would be concerned that they would break easily. Also, the point of the Prismacolor pencil can be easily altered using sandpaper. This is a more fussy job with a less durable result using 0.5mm lead.

No matter what instrument is used for layout, visibility and accuracy are greatly enhanced by using proper lighting. The two simple rules are strong and adjustable. Strong mostly means close, and the light source must be moveable to avoid glare and to cast shadows only in favorable locations. Every effort should be made to set up good lighting.

White #734 sharpened, I’m ready to indulge in Claro.