Shooting is a gateway skill to precise hand tool woodworking. So get started by shooting with the planes you have.

The basic requirements are:

- Mass. You want substantial momentum to firmly and steadily carry the blade through the cut after you get it started, especially for end grain shooting.

- The side of the plane should be square to the sole. If you only have a not-so-great plane, use tape to shim the side. I did this with my old Record jack plane when it was the only one I had. [Please see in the Comments section reader Michael’s germane point and my lengthy reply for more details on the squareness issue.]

- It helps a lot to have a comfortable, secure grip to consistently apply pressure where it is needed. Dedicated shooting planes have this feature.

- The blade must be sharp. Sharp! A dull blade is not only harder to push through the cut, but accuracy will suffer as the plane and the blade itself deviate from a true path.

For end grain shooting:

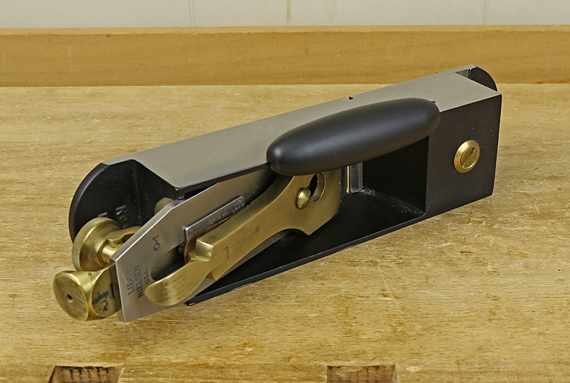

Best: a dedicated shooting plane.

I use the Veritas shooting plane, and love it. Comfortable and accurate to use, it meets all the requirements above. The adjustable-angle handle properly and comfortably directs pressure, and the 20° skew really eases the blade through the cut. The bevel-up design is easy to set up and adjust, and provides excellent support to the blade close to its edge.

Is it worth spending about $350 dollars on a plane just for shooting? In view of all the other expenses involved in woodworking, yes, it is. (See the first sentence of this post.)

Lie-Nielsen also makes a great shooting plane, which I have had a chance to use briefly. This massive tool uses a bevel-down design and a skewed, Bedrock-style adjustable frog. Personally, I like the Veritas design and features, but both merit consideration.

I use a straight edge blade for end grain shooting – no camber.

Good: a bevel-up bench plane.

The Veritas BU jack plane is perhaps the most versatile plane of all, and a good shooter. The BU design gives good blade support, and makes it easy to swap dedicated blades for its varied uses. You can get a decent grip on this plane for shooting.

Adequate: a bevel-down bench plane.

I used a BD jack and jointer for shooting for years. I do not consider these ideal but they can get the job done. Don’t let anyone tell you that you “can’t” cut end grain with a bevel-down plane. Use a sharp blade, and set the chipbreaker close to the edge to reduce deflection.

Gripping a bevel-down bench plane for shooting may be a bit awkward for some. With the jack, I squish the base of my thumb behind the side hump and plant four fingers on the lever cap. A grippy glove can help. (So then you’ll have one on both hands.)

For long grain shooting:

Compared to using a plane with the blade on the bottom (the “regular” way) this is just a matter of different manual mechanics. The plane is not running in a track as in end grain shooting.

So, a BU or BD bench plane is fine, as long as it has decent mass and stability, the side is square to the sole, and you can get a decent grip. And . . . the blade is sharp.

I like my Lie-Nielsen #9 “iron miter plane,” which I’ve dedicated to long grain shooting, because its beefy, boxy design makes it stable through the stroke, and it handles exceptionally well with the “hot dog” grip. This is a bevel-up design with a 20° bed. (Hmm . . . ) Unfortunately, I don’t see it on their website any more. Veritas sells a somewhat similar plane.

I keep the #9 set up with a straight edge blade, mostly because it is easier to maintain and works well for the thin stock that I’m usually using when long grain shooting. A mild camber, such as for a jointer plane, is also a good option, especially if you will be long grain shooting thicker stock, or if you are also using the same plane and blade for general tasks.

All well and good, but you’ve missed the Record T-5; with the handle moveable from side to side, it’s good for both left and right handed shooting. It’s a bevel down, but with a sharp blade, it works just fine on end grain and long grain.

Basic photo is at http://www.record-planes.com/files/2011/09/MainPage-Record-No-T5-Technical-Jack-Plane.jpg I wish mine looked so good, but it does the job for me.

Thanks for your comment, Polly.

This post is aimed at the key characteristics of shooting planes, some options, and my preferences. It is not meant to be a comprehensive list of planes that can be used for shooting. As such, the T5, which has been out of production since the 1970s, is not included. I see that a few are available on Ebay.

Nonetheless, this does bring up the option of drilling and tapping the side(s) of a bench plane to install a removable male-threaded handle, which could be shop-made or purchased from Rockler, Lee Valley, etc. This could help with gripping a bench plane used on its side.

As usual, there’s yet another way to do things in woodworking.

Rob

Thank you for writing this post. It clarifies the questions I had about shooting planes. The Lie-Nielsen #9 looks very interesting. I guess they were not selling enough of them to keep it in production?

Hi,

This may not be the right place for this question, if so I apologize, but no one really seems to talk about shooting at all so I don’t know where to ask this…. I have a problem getting perfectly square ends when shooting them on my shooting board.

I have a homemade plywood shooting board and use a Record 5 1/2 on its side to shoot. I’ve checked everything, and everything is square to each other and the plane is sharp, however when shooting end grain the plane takes more off the near edge (closer to the front) than the back edge. Flipping the piece of over I can take more off the other side and so ultimately get a square edge, but by default the plane will not take an even shaving across the whole of the end grain. Is this normal? Have you experienced this before? Am I doing something wrong?

any ideas or help you could provide would help with my frustration.

thanks

Matt

Pascal,

Who knows? Anyway, the Veritas shooting plane is wonderful for end grain shooting, and you can use it or a bench plane for long grain shooting. Good luck!

Matt,

Yea, things like that can be frustrating. I will try to help by answering your question in a separate post. Please stay tuned.

Rob

Thanks for the article.

Just wanted you to know that Veritas shooting plane does not have 90° angle and its intentional. So “square to the sole” is not that critical for the job as long as you have lateral adjustment for the blade.

Michael, thank you for the comment.

I am well aware that the Veritas shooting plane’s sole and side are not exactly at 90° to each other. “The side of the plane should be square to the sole” is a statement of the general requirement for a shooting plane.

Indeed, Veritas describes their plane as “ground so that the sole is flat and the side is square to the sole.” However, in an addendum sheet that accompanied the plane when I bought it, but not part of the “Care and Use” pdf on their website, Veritas explains that the plane is actually ground to 90° or less to a tolerance of .003″. My plane happens to be at about the limit of this one-sided tolerance.

My guess is that Veritas, even with their awesome manufacturing capabilities, needs to make sure that the angle is never greater than 90°. If it was significantly greater than 90°, the side of the plane, down near the corner, might not run as snugly against the registration track in a shooting board.

Anyway, this amount of “error” is much less than, for example, the sides of my old Record plane that I used to shim with tape. The 3 thou is over a length of about 3 1/4″. That translates to only about 2/3 of a thou over a 3/4″-thick workpiece. This is easily compensated by using the Norris-style lateral adjustment to create an uneven blade projection across the width. This causes no problem with cutting. The blade cannot repeatedly take a thicker shaving on one side (as would happen with a bench plane used in the usual manner) because the shooting plane runs against the track, not on the workpiece.

The practical consequence of this is that you cannot just look to create an even blade projection and go to work. Rather, you have to take a few test cuts to see if your compensatory uneven blade projection is producing an exactly square cut on your workpiece. In practice, this is easy, and Veritas has thoughtfully incorporated set screws to help maintain your lateral adjustment setting. Of course, this same adjustment maneuver is being effectively used to compensate for any other sneaky imperfections that might exist in your overall shooting setup.

The key point is that any system with multiple precision components such as a shooting setup will inevitably harbor imperfections and so compensatory mechanisms must also be built into the system.

Rob

Hi Rob-

Not sure if I commented on this before. If I did, you can edit it out without repurcussion.

I also read that LN eliminated the Iron Miter #9 from the product line. Not being one who takes no for an answer, I sent them an email asking if they planned to re-introduce or do these on a request basis. I was prompted to do this by something I read on Tom Fidgen’s website.

As typical of LN, one of the most customer-oriented companies in business today, I got an email back. They wrote that if demand is sufficient, they do make limited batches of discontinued tools. If I was interested, they would add me to the list of those requesting the tool. As luck would have it, within 2 weeks I got another email, writing that they will book my order and I will have the plane in a few weeks. Needless to say, within a few weeks, I had a nice shiny #9 in my hands.

So, the moral of the story is, don’t accept NO for answer.

BTW, I am VERY pleased with my decision to purchase the #9.

— Steve.

Thanks, Steve. L-N is a great company. Glad you like the #9.

Rob

The Veritas BU jack plane you show seems to have a better shaped handle than on the current models. It looks more like a LN handle did you replace the Veritas original with one of theirs or did you make your own?

Hi Peter,

The replacement handles for many of my handplanes are by Bill Rittner. Here is a post with the explanation and a link to Bill’s website:

http://www.rpwoodwork.com/blog/2011/04/11/great-replacement-handles-for-veritas-bevel-up-and-scraping-planes/

Rob

Thanks Rob. I’ll check out Bill Rittner’s site.