A bench hook is a handy workbench accessory, mostly for crosscutting small parts. This version works well with both Western push saws and Japanese pull saws.

I try to keep workshop jigs and fixtures as simple as possible (“but no simpler,” per Einstein) and this one is no exception. It is constructed from plywood and maple, using simple glue and biscuit joints. The base is 12″ wide by 9″ deep with a 13/16″ high by 1″ wide maple fence at the middle and a 2″ wide cleat for hooking the bench. It could just as well be screwed together. The fence is shortened on the right side for a right-handed woodworker.

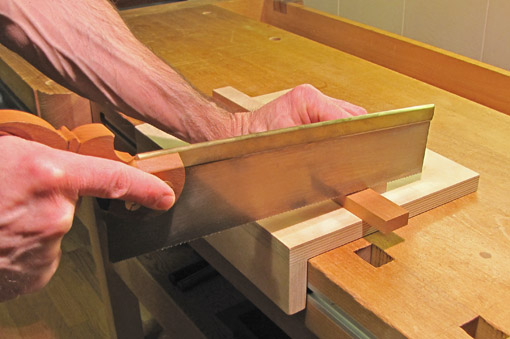

For use with push-stroke saws, the jig is simply placed on the bench top with the cleat catching the front edge of the bench. The work is held in place by hand with forward pressure against the front side of the fence. Aided by the sawing pressure, this also holds the bench hook itself in place.

For use with pull-stroke saws, the work is placed against the back side of the fence. Since the sawing pressure is toward the user, it will pull the work against the fence but will also tend to displace the bench hook. This is not a problem for light work because I can lean forward the heel of my left hand against the fence to stabilize the bench hook while gripping the work piece against the far side of the fence with the rest of my hand. For more substantial pieces it is better to secure the bench hook in the front vise of the workbench.

I do not generally use the end of the fence as a guide for the saw, and do not use a fence with 90̊ or 45̊ kerfs, though some may prefer these options. I work to a line marked on the wood and just eyeball noncritical cuts.

This bench hook is unscarred because it is new, replacing one of the same design that got too beat up. As with so many tools in woodworking, it takes a long time and many situations to get a real sense of the effectiveness and versatility of shop jigs. This design has served well over many years so I continued it for the new one, only making it slightly larger.

The bench hook comes in handy for more than sawing. All sorts of work on very small pieces, such as paring and chopping seems to get done on the front side, against the fence. I do not shoot on it; I use a shooting board for that.

Once again, simple and proven effective.

Flexible, easy to replace, and always a work in process. I like the design and the idea that it takes many hours to truly judge whether it works for you. I have to keep that in mind when I’m discarding yet another jig and starting from scratch!

good idea. I especially like the last picture – i wouldnt have thought to use it for those sorts of things.

Good idea.

I built a bench hook a while ago and it lives on my benchtop. I find it indispensable for small cutting jobs and as a backer when I’m using hand tools. I built a push saw style and have found that it works poorly for pull saws. I don’t like the idea of a separate jig just for pull saws, so I like your design.

I’ve been planning to make a bench hook suitable for pull saws and thought another way to help secure it would be to put one or two pegs on the bottom that fit into dog holes on the bench.

Thanks for the comments.

Jim: Sounds like a great idea. It would have to be a snug fore-and-aft fit in the dog holes to avoid moving during sawing. Please let us all know how it goes if you build it.

Hey, now that I think of it, I guess a bench hook for pull saws could simply hook over the edge of a tool well at the back of the bench, or just the back of the bench itself, though it would be a long bench hook.

Many ways to work wood.

Rob

Excellent read… I especially like your last statement “simple and proven effective”. For household projects especially if you are not a pro or not an expert or a trying hard simple is such a very favorable thing.

Thanks for reading, Jeremy.

Hey, to make the device even simpler to use, you could extend it the full width of the bench so that it hooks on both sides. Then you wouldn’t have to push the hook onto the bench with your off hand, and could focus on steadying the hook. Something like what Tom Fidgen describes in his book.

Simon,

Good idea. It would have to be a snug fit to avoid rattling. A snug fit in June would be a loose fit in February so a shim or wedge system may be needed. Oops, I think that’s getting too complicated for me.

If you try that design, please comment again to let readers know how it goes.

Thanks.

Rob

Hi Rob-

You and Tom F. got me hooked on the bench hooks (bad pun). But you can’t have only one if you’re working on longer pieces. So I now have about 4 or 5 of them to support stuff all along the bench top. Tomorrow I’m going to try putting a 3/4″ dowel into a hook to anchor it in a dog hole. We’ll see how that works out.

–Steve.

Steve,

I use a bench hook for work on only small pieces of wood, but of course there’s more than one good way to do things. Good luck with your work and thanks for reading.

Rob