The Domino sure makes joinery easy: fast layout, cutting parts directly to length, mortises in a flash, no fussy trimming of tenon shoulders, and no trips to the sharpening bench. This may come at a price, however, if you fall into the seductive trap of machine woodworking, which is letting the limitations of the machine govern too much of the aesthetic and structural design.

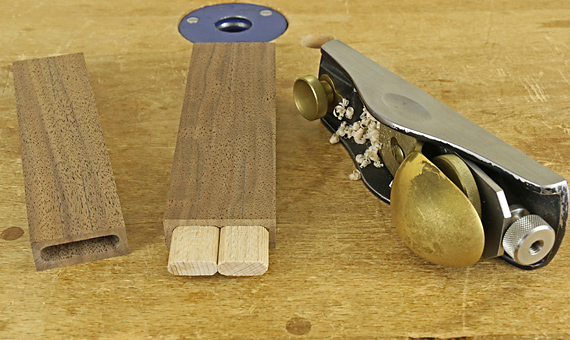

Let’s look at some possible frame or rail joints made by the Domino DF 500. The photo above shows the “tenon” half of the joint where the long grain of the Domino matches that of the frame member. The two on the left are fine by me. The third from the left is marginally acceptable. The one on the far right is awful.

A little arithmetic backs up what I think most of us would intuitively see as a waste of potential glue area in that last joint. The flat width of the Domino is 13.7mm, or 0.54″, irrespective of its thickness. With a tenon insertion of about 1″ (half the length of the 50mm Domino), we get a total effective glue area of about 1/2 square inch x 2 (for both sides of the tenon) = 1 square inch. I don’t count the rounded areas because they are not good glue surfaces.

At the other extreme, since the rail is 1 ⅞” wide, a slip joint or full tenon would give about 7 square inches of effective glue area! The demands of the design might not need all of that, but giving away 86% of the potential glue area is too much to sacrifice for convenience. I want my work to last.

How can we increase the glue area, at least somewhat, and retain the convenience and speed of the machine? As an example, in the photo below, on the right, the same 1 ⅞”-wide piece has two slightly overlapping Domino mortises. I simply trimmed the Dominos on their inner edges with a block plane to make them fit.

The piece on the left (the marginally acceptable one in the top photo), as another example, has two mortises that overlap a lot to make one wide mortise, wider than widest setting on the machine. It would be easier to make a loose tenon for this than to divide Dominos.

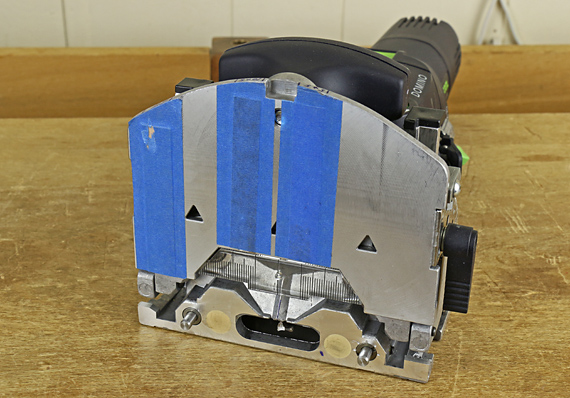

To get the Domino machine to chain together small mortises into a neat, continuous mortise that has no steps in the walls (photo below), the fence must be exactly parallel to the motion of the bit.

My Domino DF 500 – yes my $800 Domino – did not meet this level of accuracy. The machine cannot be adjusted for this, so I carefully shimmed the fence. That was complicated because the shims have to essentially create a new fence surface that is at a very slight angle to the original one.

I had sent sample mortised pieces to Festool but they told me it was within tolerance. Well, it was not within what I tolerate in my work. This is not a tool review, it is simply an account of my experience with the machine I bought.

The general point of all of this is to take charge of your woodworking machines, and not let them lull you into woodworking that you know is second-rate.

The side walls of the mortises look fairly small. In the failure study I recall seeing, the traditional mortise and tenon joints failed by breaking out through the side wall, so I wonder if these joints would be stronger with a smaller domino and larger side walls.

Excellent points Rob. You should be an engineer!

I actually enjoy doing mortise and tenons by hand. It is pretty fast. Plus I often like to show dovetails on the front rails of case pieces. Just a nice detail that shows hand workmanship and can look great, IMO.

I also never learned to use a dovetail jig. It’s fun to do them by hand and sometimes I try to get the pins really thin, which a router cannot manage, just to advertise that it’s done by hand :)

Yea, Adrian, the sidewalls are a bit thin, but the discussion is about glue area and I wanted to give the Domino a fighting chance by using 8x50mm instead of 6x40mm Dominos, because the former have more glue area by virtue of their greater length.

Yes, Bill, I shoulda been an engineer! Coulda been a contenda.

And yea, sometimes we can do things faster just getting straight to the work by hand, rather than figuring out work-arounds for machines.

Rob

Hi Rob-

I agree about the glue surfaces. However, I was sold early on with the Domino. Spent all the money that it required. Now it basically sits on my shelf unused.

I now cut my mortise and tenon joints by hand. The accuracy and glue surfaces are dependent on my hands not a machine.

I ran into the same misalignment issue as you did. Got the same answer from Festool. You would think that a company with their reputation for quality and tolerances would be more responsive and acknowledge they have / had an issue. But the answer is no. I had to use the same tape kluge as you did. $800 tool with masking tape to make it work acceptably. Unacceptable.

I am looking into selling some of my Festools as I get more and more into hand working.

Just my rant.

— Steve.

I hear you, Steve. I still use the Domino but more guardedly. Festool makes good tools, and they are innovative, but overall, Festool is overrated and way overpriced. 80 bucks for a plastic box ought to be a big hint for everyone.

Rob

Hi Rob!

I must thank you very much for shimming a bell about this domino problem. Thankfully, I read this blog BEFORE buying my Domino XL and planned to make extensive tests on the machine so I can take advantage of the 30 days warranty and return the tool if it doesn’t meet my expectations. I already got the “sorry, it is within tolerance” argument with my Festool routers so I didn’t want to take any chance with this hard won money on the XL.

Well, it turned out that my new Domino is going back to the dealer. If I try the Domino as it is supposed to be used by their instruction manual, everything seems fair… apart from the fact that the sight gauge in the viewing window could not be adjusted correctly: I should move the sight gauge more than is allowed for it to be accurate! Here is the test I did:

Take the 12mm bit, use the Wide setting. Take a large block of wood (about 2″ X 6″ X 18″ long) so that the fence is fully supported at any position. Mark 6-8 lines spaced 18mm apart at the center of this block of wood. Plunge about 20mm deep (so as to avoid user manipulation errors) by centering the domino on each mark (using the sight gauge), one by one. Observe the very wide mortise created.

In my case, I add a “scalloped” mortise and I can see that it is not an “user error” since the scalloped surface is very very consistant, showing exactly what you described: the fence is not in the same plane as the side-to-side motion of the bit.

I did the exact same test by using the “base” instead of the fence as the reference and got the exact same result (I previously check that the fence was in the same plan as the base so this was not very surprising).

I found that a shim of 0.070″ (yes, more than 1/16″!!!) at the right side of the fence did a near perfect mortise. So it was not “user error” :-) I made a lot of mortise with this shim and whatever setting I was using, the mortise was near perfect.

A way to check the mortise and see the consequence is to put a card scrapper inside the large mortise so created: you can clearly see where the glue will fail doing it’s job. I had about 75% of the surface where the gap was (to my sense) too large to make the glue do a good job.

Thanks, Ben.

That is exactly the type of test that clued me in to the built-in, non-adjustable inaccuracy in my Domino. I was trying to “chain” mortises to use the machine as a mortiser apart from its use with dominos. I got the stepping effect as you did.

This manifest inaccuracy had been causing alignment problems in some of my ordinary domino joints, which I had previously attributed (incorrectly) to manual error.

The Domino is a great concept and can work well if used in an appropriate role in building. The problem, in my opinion, is that Festool likes to tout their tools as being uber quality, worth the exorbitant prices they charge, but that just isn’t always so.

I’m still trying to figure out how a plastic box is worth $80.

Oh, excuse me, a Systainer.

Rob