There are the good reasons for using a diamond stone as a nagura. This is not a novel idea – the intent here is to present a clear rationale for it. However, there’s also a significant practical problem involved.

All of this applies to synthetic finishing waterstones. I think most or all of this probably also applies to Japanese natural finishing stones but I defer to those with more knowledge about those.

The reasons for a diamond nagura:

1. It’s fast. The slurry is raised faster and the surface of the stone is refreshed faster than with any other type of nagura that I have tried. Whatever you perceive to be the benefits of these effects, as discussed in the previous post, they arrive faster with a diamond nagura.

2. The slurry consists of grit solely from the finishing stone; no new grit is added. This removes the uncertainty of introducing another grit, often unknown, from a stone nagura, along with the uncertainty of the amount of it that gets into the slurry based on the relative hardness of the bond in the main stone versus the nagura.

3. It is very capable of crushing the grit in the slurry. I first learned about this several years ago from So Yamoshito, a Japanese tool vendor in Australia and expert on Japanese natural stones. I wrote about it then. The rationale for specifying 1200 grit diamond is that it is fine enough to readily crush the loose fine grit in the slurry yet coarse enough to raise the slurry quickly. The latter effect is apparent.

I can’t directly prove the crushing theory. Furthermore, for it to be of value, the crushed particles would have to retain good cutting ability as finer particles. After working with this for years at the sharpening bench, it does seem borne out by the blade edges it produces.

By the way, what about just using the slurry created by flattening the finishing stone with a coarse diamond stone, say 220 grit? Yes, that’s pretty good but the crushing effect is better with the 1200 diamond. Also, a lot of water is used in flattening and the process tends to swipe the slurry off the finishing stone.

Now for the problem. When you rub a 1200 grit diamond stone, even an Atoma with its surface made of tiny dots of grit clusters, on the wet finishing stone, it sticks like crazy. This is very annoying and then it tends to carry away much of the slurry when you remove it.

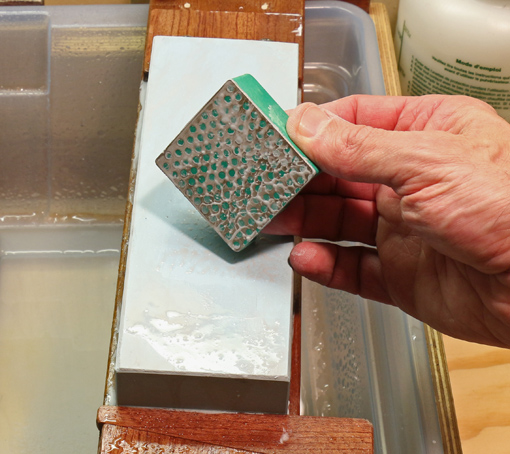

I tried using smaller continuous surface diamond stones but they were no better. Then I tried a DMT 6″ x 2″ inch 1200 diamond stone with the “polka dot interrupted surface.” This reduced the sticking but still not well enough. It needed to be smaller.

The little DMT polka-dotted pocket stones were too thin to grip in my fingers. So I hacksawed a 2″ x 2″ section off the 6″ x 2″ stone, which you can see above. It works pretty well. The small size and the perforations eliminate most of the sticking.

Note that I do not consider flattening to be a function of the nagura. In fact, a reasonably evenly-distributed rub of the small diamond nagura should not significantly change the flatness that has already been established well by a coarse diamond flattening plate. I flatten stones at the end of a session when they are fully wet and so they are ready to go for the next use.

The best solution, I believe, would be a 1200 grit diamond nagura, about 2″ x 2″, with narrow channels extending to the edges that would reduce sticking and allow the slurry to flow away from the nagura and remain on the finishing stone. I am working on prototypes using 1″-thick ABS plastic for the base and various applied diamond surfaces. I’m hoping this results in a nagura that is the bee’s knees, but in any case I will report on this soon.