This is a tool that we all use but gets little attention. As usual with tools, there is a range of quality from barely usable to excellent, and to do quality work, it pays to know the differences.

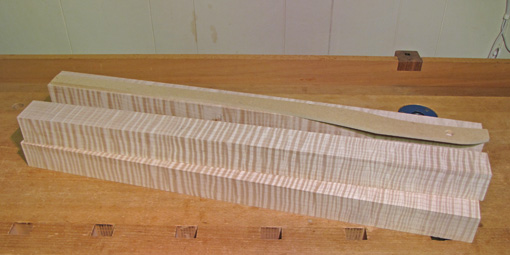

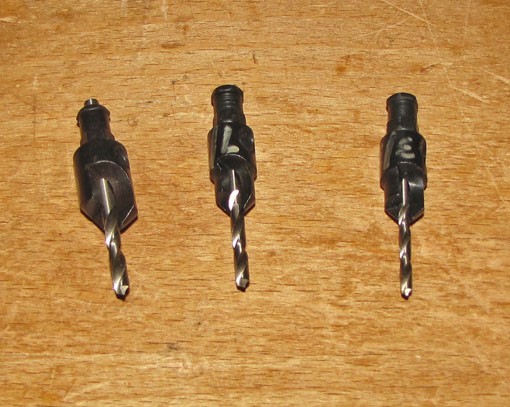

Let us consider the tools in the photo at the top, from left to right:

1. This type is the ubiquitous hardware store/home center DIY countersink which has little role in quality furniture making. Its five flutes are symmetrically arranged and present a thick, dull cutting wedge to the wood. For these reasons, it chatters badly, meaning that it bumps and jumps as it cuts, producing radial bumps on the countersunk wood surface. Save this one for home carpentry projects with CDX.

2. This is a countersink/deburring tool which is excellent for metal working, but also cuts quite smoothly in wood. It cuts fairly slowly in wood compared to the other designs, but it does not tend to chatter and leaves a good surface.

3. This is a quick-change hex shank bit which is quite sharp and generally cuts fast and well, though it has some tendency to tear the wood and chatter a bit, especially if it is pushed hard.

4. The Beall countersink is an excellent quality tool and a favorite of many woodworkers. The design and weight virtually eliminate chatter, and it cuts smoothly. I find it somewhat bulky for most work though. It certainly is handy for large holes.

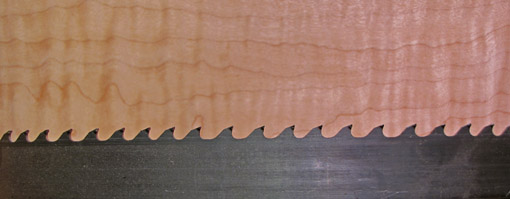

5. This is the best one. Lee Valley used to make these but I cannot find them anywhere now. As seen in the photo below, on the right, it has radially asymmetric flutes which present sharp, narrow cutting wedges to the wood at low angles. These design elements produce a countersink that never chatters or tears. It can be sharpened with a small diamond paddle. I wish Lee Valley would make them again.

The DIY clunker is on the left in the photo below.

Hey, I counted 18 countersinks here. Hmm, is it possible that I have a, ah, countersink problem?

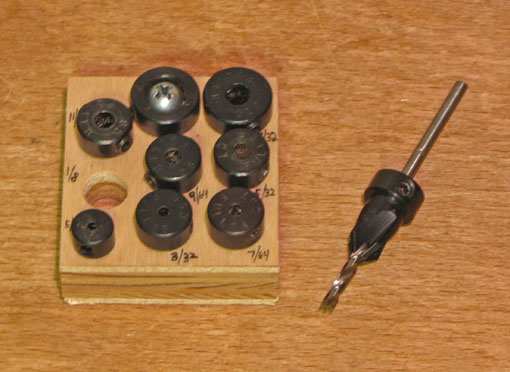

The Fuller set, below, are countersinks that attach with set screws to drill bits. These are most useful in a drill press to bore a hole and countersink in one pass to a specified depth. They can also produce a clean counterbore for plugging. They run chatter-free but have a tendency to clog. Excellent quality.

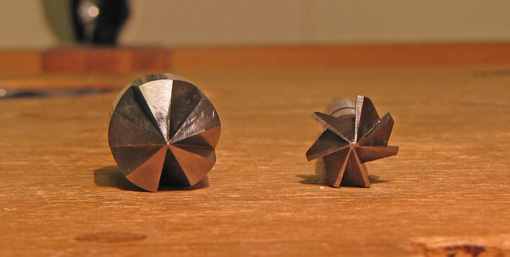

Below, left, is a narrow (about 1/4 inch) Weldon countersink, similar in design to #2, above. It is handy in tight spaces, using narrow screws. To the right is a piloted countersink that I use only for remaking holes in hardware. Lee Valley sells them in various sizes and they can really save the day for hardware problems.

Finally, below are some more DIY tools for a quick change chuck available from Lowe’s. These are certainly not at the quality level of the Fuller tools, but are not bad for fast, less finicky work.

As always, match the tool to the job. And, again, hey Lee Valley, I wish someone would make a nice countersink like #5, above. If any readers have found one, please comment. In the meantime, the Beall is probably the best choice, or, for a smaller tool, the countersink/deburring design (#2, above).