I have had my eye on carbide segmented cutterheads for a while. After studying the options and particularly after reading Glen Huey’s excellent article in the February 2011 Popular Woodworking, I decided to get the Byrd Shelix cutterhead for my DeWalt DW735 planer.

Most of my pieces use highly figured woods. I had been having trouble getting good surfaces from the planer on some of these difficult gems of nature, despite using appropriate technique. I don’t expect a machine planer to yield a finished surface, of course, but tearout surprises can require corrective handwork sufficient to change dimensions and relationships. Parts meant to match and reference surfaces were disturbed; there was too much backtracking and unpredictability. This affected my work flow and was frustrating.

In considering a segmented cutterhead, I first had to decide if the DeWalt DW735 was a good enough machine in which to invest. After years of use, its design, quality, and reliability are proven. So, primarily for the joy of using my beloved figured woods, I took the plunge: $447 for a Byrd Tool Shelix – “she” for shear, and “helix”. (Sounds like a part to soup up a motorcycle or something.)

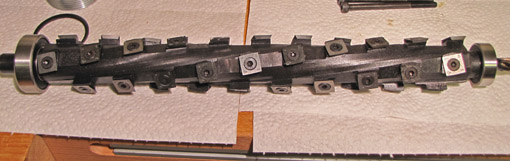

Below is the Shelix in all its medieval-looking glory. Thankfully, it comes with the bearings attached.

In future posts, I will discuss the basic design and performance of the Shelix, and how this tool is integrated into the work flow of a project. The latter issue is the most important one and required the most thought to make this a sensible investment.

The post immediately following this one lists tips for installing the cutterhead.

I did the same thing last year, but was dissapointed with the extra power it took. I had to shave very small increments or it would blow the circuit breaker on a dedicated 15 amp circuit. Are you having the same problem? I was wondering if the motor could be wired for 220.

Dean,

The DW735 is rated at 15 amps. The Byrd draws more amps than the standard knives, probably because the segmented cutterhead is always engaged in the wood, unlike the action of straight knives which engage and release. But a 110V-15A circuit is borderline in any case. I dislike 110V-15A circuits in general for a shop.

I run it on a dedicated 110V-20A circuit with no problems. I recently talked with a DeWalt technician at a local DeWalt service center and he has told me that the DW735 cannot be rewired to 220V.

Time to call the electrician, I guess.

Good luck, and thanks for reading the blog.

Rob