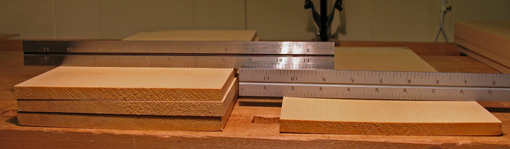

These boards, about 7 inches and 5 ½ inches wide, were originally a bit over 2 inches thick and were resawn into four slices. I had monitored the moisture content of the original boards over a few months in the shop and was confident they had equilibrated to the ambient humidity. Immediately after resawing, the inner slices measured the same moisture content as the outer slices, proving there was no moisture gradient through the thickness.

The photos above show the slices immediately after resawing, set up in their original positions. Note the inner boards are flat, but the outer boards are mildly cupped, concave on their inner faces. This immediate distortion is due to internal stresses in the wood, not moisture changes.

I could have predicted this by using the method discussed in a previous post on this blog. Of course, I did not follow my own advice. Notice the outer right board in the wider set. I sawed it too close to the desired finished thickness and now I will lose some thickness after flattening away the distortion. Had I properly anticipated the distortion with the prong sample method, I would have made the outer slice thicker to compensate. Having been reminded of my lesson, I did this when resawing the narrower board.

The steel rules lying across the slices of the wider board show the inner slice is flat while the outer slice has about a 3/64 inch cup. That’s not so bad, but the total loss of thickness is double that amount after both faces are flattened. A moisture gradient through the thickness of the original board, if it had been present, could have exacerbated the problem.

This is yet another reminder (note to self) to understand and watch the wood. That’s always good advice.

now undeerstood about real reason of distortion. thanks.

Benki,

And this type of distortion can usually be predicted with the prong sampling method. Watch the wood and good luck,

Rob