For several months I have been using an Atoma 1200 diamond stone to improve the action of the finest Shapton stones when I want a really excellent edge.

For flattening Shapton stones, the Shapton Diamond Lapping Plate works wonderfully fast and well. The grit size is listed as 54/45 micron, approx imately equivalent to P280/320 sandpaper. It is manufactured to a flatness tolerance of +/- 3 microns, which is about one ten-thousandth of an inch!

imately equivalent to P280/320 sandpaper. It is manufactured to a flatness tolerance of +/- 3 microns, which is about one ten-thousandth of an inch!

However, to go beyond the task of flattening the stone, I wanted to improve the cutting qualities of the stone’s surface and the slurry. I turned to the expert advice of So Yamashita who recommended the Atoma 1200. This is used essentially as a nagura substitute. (The particles of a nagura are coarser than those of the finest Shaptons.) The Atoma has an extremely even spread of diamond particles on its surface which, as they rake particles off the Shapton, crush them into smaller pieces creating an ultra fine paste as well as finely conditioning the Shapton’s sharpening surface. It does this specific task better than the coarser Shapton Lapping Plate. This also gives the stone surface a nice feel under the blade which improves my sense of the blade’s contact on the stone.

So further suggests, for the very finest edge, to rinse the slurry and polish the edge with almost no water. A slurry can slightly round the edge which would work better for a tougher edge for coarser planing.

So is outstandingly knowledgeable in the field of Japanese woodworking tools, especially sharpening stones. I do hope I am presenting his explanations accurately; any errors are mine.

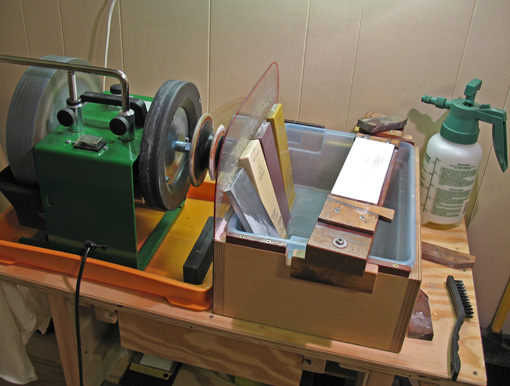

I can certainly say that this system is giving me very good results. The Atoma diamond stones are available from Japan-tool and, I believe, from Hida Tool. I have no financial interest in the sale of these; my suggestions are for the benefit of fellow woodworkers. The sharpening station set up that I use, in the photo above, is detailed in the October 2007 issue of Popular Woodworking magazine.